Expandable Polystrene (EPS) production line and moulding process

Estechtic | EPS processing and recycling machines

Overview:

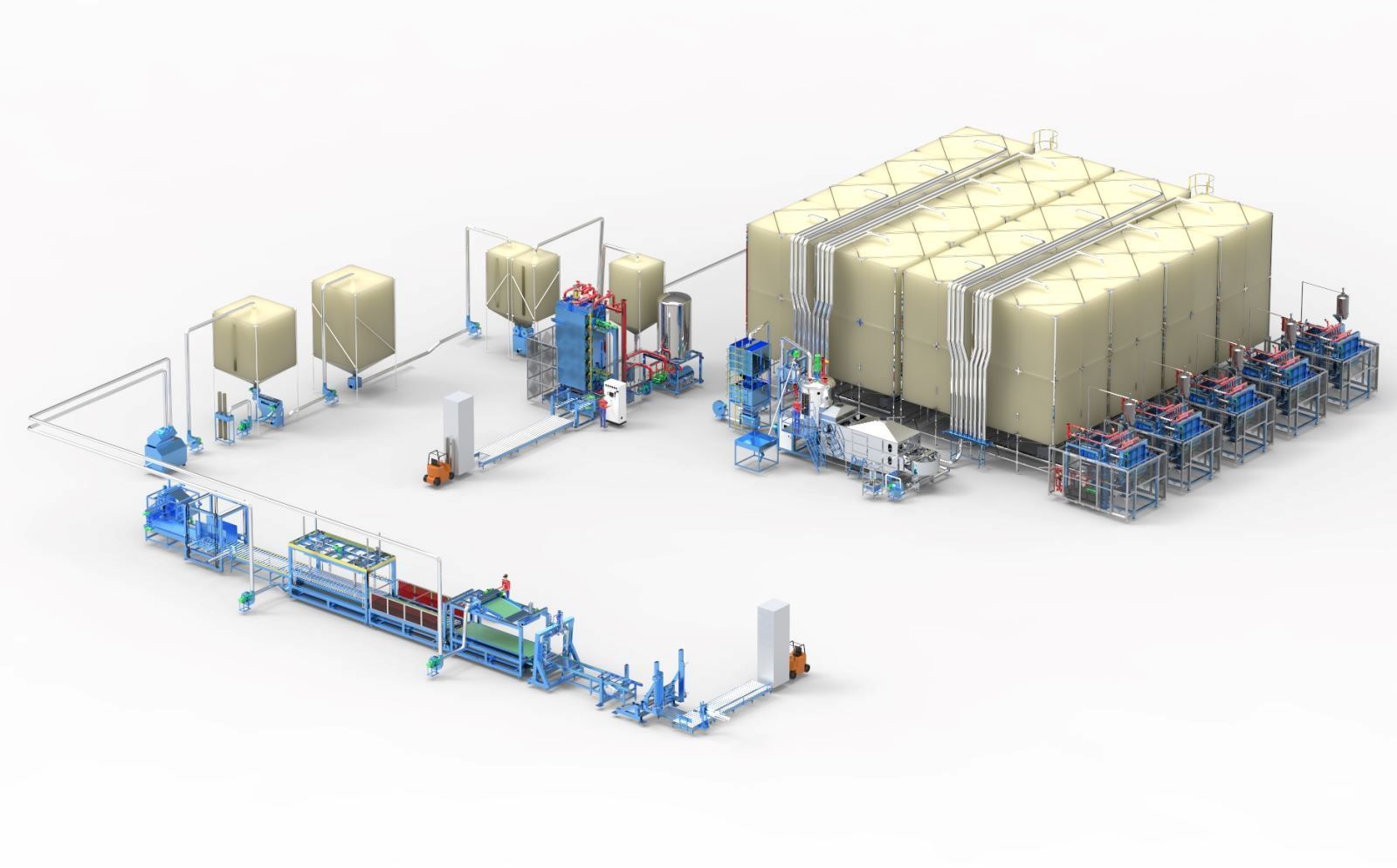

The production line with various types of machines and equipment is required for the production of EPS products. Depending on the kinds of products, a plant could be a EPS block moulding plant, a EPS shape moulding plant or both. It is essential to have auxiliaries such as steam system or cooling water system, along with the main production machines. Therefore, it is highly recommended to get a full turn-key solutions for new EPS plant projects. The main machines and equipment in an EPS production plant are as below:

Machines and equipment for EPS shape and block moulding plant:

- EPS pre-expander: used to transform EPS raw material into the beads with constant density

- EPS silos: used to store beads for aging and stability

- EPS shape moulding machine: used to produce shaped EPS products

- EPS block moulding machine: used to produce EPS blocks

- EPS cutting line or cutting machine: used to cut EPS blocks into sheets

- EPS recycling system: allows using scraps after crushing into beads

- Auxiliaries: steam boiler room, water cooling system, compressed air system

Illustration of the EPS shape and block moulding plant: